How Can Sheet Metal Material Handling Help your Business?

SteelStack Sheet Metal Material Handling Solutions - The 5 Benefits

Sheet metal material handling is a critical aspect of various industries, including manufacturing, construction, automotive, aerospace, and many more organizations. It involves the careful and systematic management of sheet metal materials, such as steel, aluminum, and copper, from their arrival at the facility to their utilization in various applications. Efficient sheet metal material handling not only streamlines production processes but also contributes to improved safety, reduced waste, and increased overall productivity. In this article, we will explore the benefits of effective sheet metal material handling and why it is essential in modern industrial operations.

1. Material Handling Efficiency

Efficient sheet metal material handling is a cornerstone of productivity in manufacturing and fabrication industries. By implementing well-planned handling processes, companies can reduce downtime, decrease waiting times, and optimize workflow. This leads to faster production cycles and lower manufacturing costs, ultimately enhancing the competitiveness of the business.

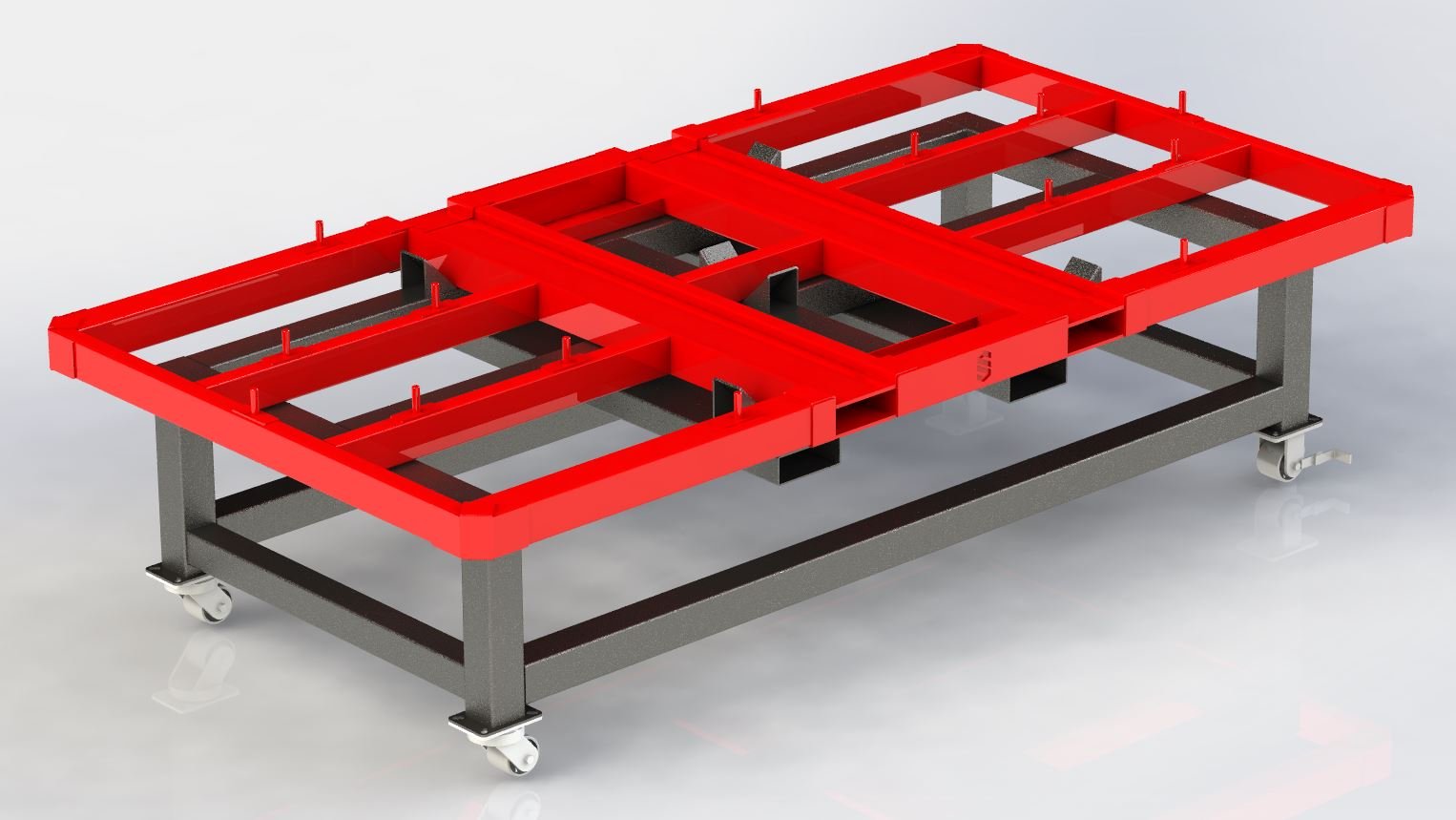

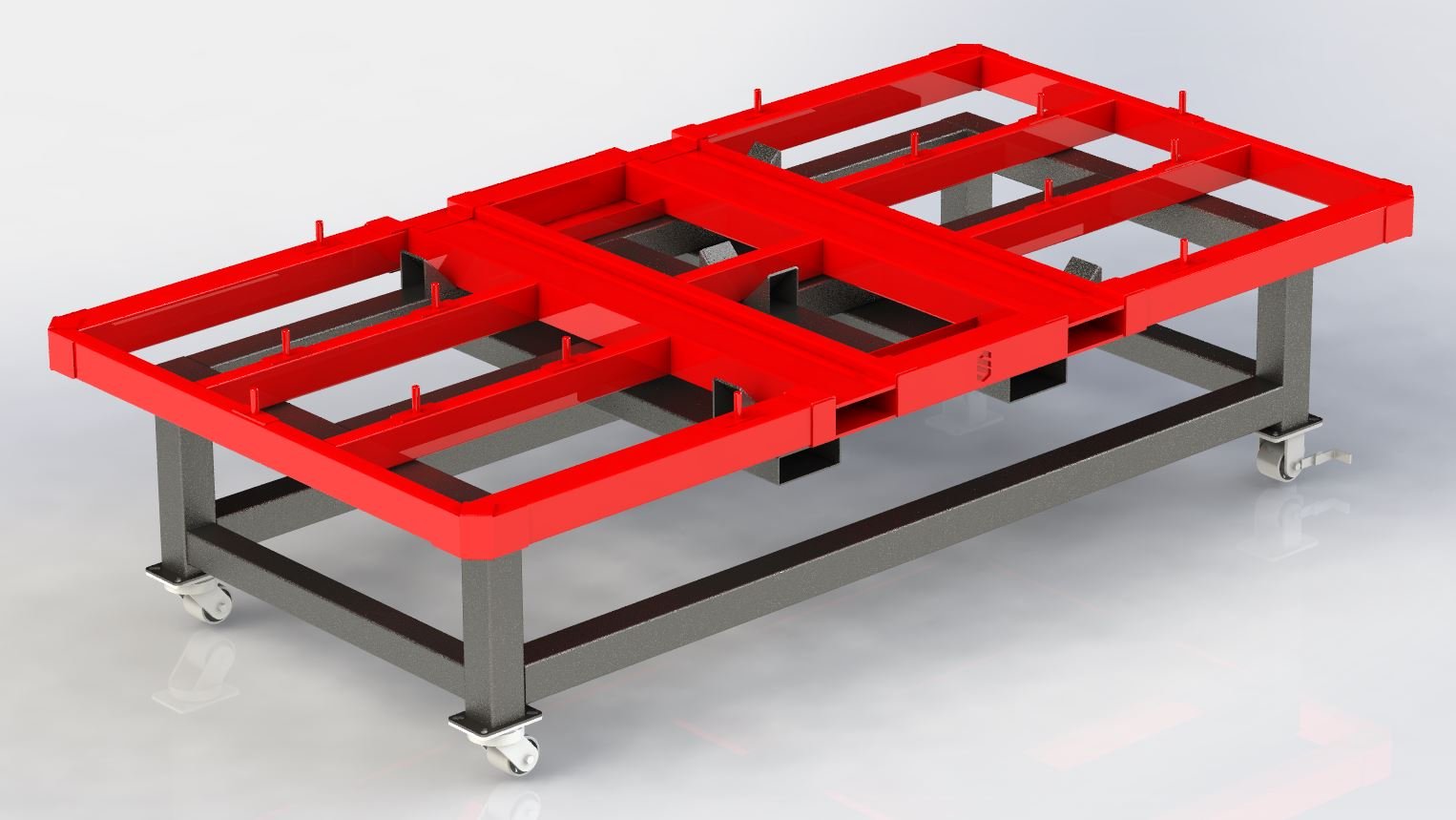

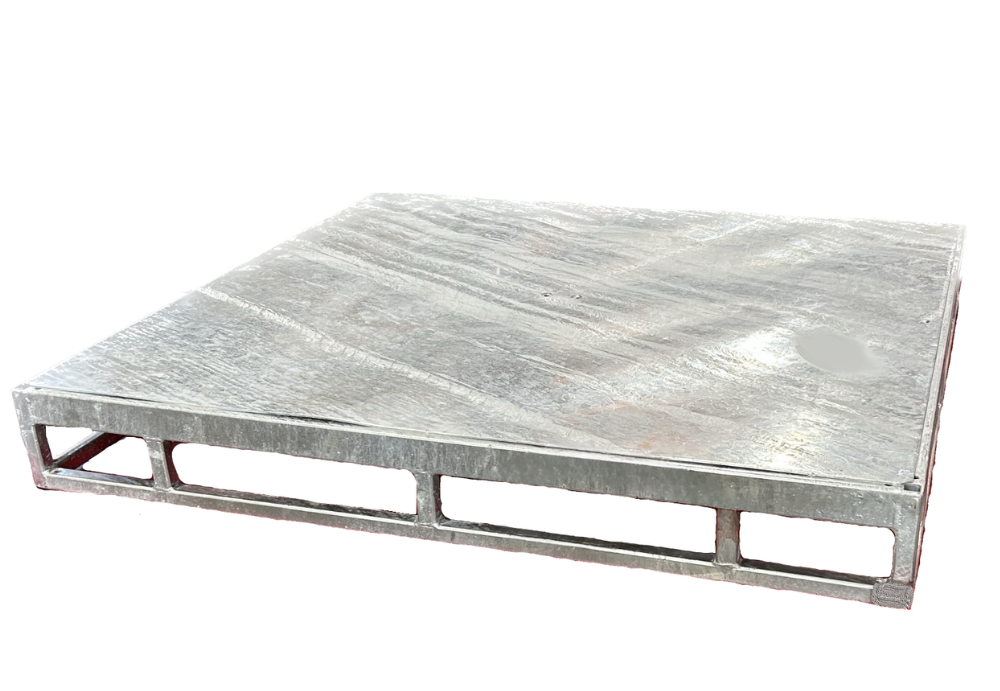

One way to improve efficiency is through the use of specialized material handling solutions like our SteelStack Sheet Metal Tower Rack and Metal Mule - Sheet Metal Handling Cart.

2. Our Sheet Metal Material Handling Solutions Enhance safety.

Efficient material handling reduces clutter and ensures that materials are stored and transported in an organized manner. This minimizes the risk of slips, trips, and falls in the workplace.

3. Waste Reduction

Your Sheet metal is a valuable resource, and minimizing waste is crucial for both economic and environmental reasons. Effective material handling practices help reduce material waste by preventing damage during transportation and storage. By protecting sheet metal from dents, scratches, and other forms of damage, companies can maximize the usable surface area and reduce the need for rework or replacement.

Furthermore, efficient handling processes can prevent the accumulation of excess inventory, helping companies avoid over-purchasing materials and reducing carrying costs.

4. Cost Savings

Sheet metal material handling, when done efficiently, can result in substantial cost savings. Reduced downtime, lower labor costs due to increased productivity, and minimized waste all contribute to improved profitability. Investing in appropriate material handling equipment may require an initial capital expenditure, but the long-term savings and benefits outweigh the costs. We also offer Financing Solutions

Moreover, efficient handling practices contribute to a positive working environment, which can lead to higher employee morale and retention rates, further reducing recruitment and training expenses.

5. Sheet Metal Inventory Control with Ease

Our Material Handling Solutions can significantly aid in inventory management for businesses that deal with sheet metal materials. Our specialized solutions are designed to optimize the storage, organization, and accessibility of sheet metal, thereby offering several benefits for inventory control:

Inventory Tracking: Sheet metal racks can be integrated with inventory management systems or barcode systems. This enables real-time tracking of sheet metal quantities, usage patterns, and reorder alerts, streamlining the entire inventory management process.

Improved Organization: SteelStacks storage Towers provide designated slots or compartments for different sheet sizes and types. This organized layout makes it easier to categorize and locate specific materials, reducing the time spent searching for inventory.

In summary, our Sheet Metal Material Handling solutions offer an array of advantages that contribute to efficient inventory management. They help maintain inventory accuracy, reduce damage and waste, enhance safety, and optimize the use of available space. By investing in the right sheet metal handling solutions, businesses can effectively control their inventory and improve overall operational efficiency.